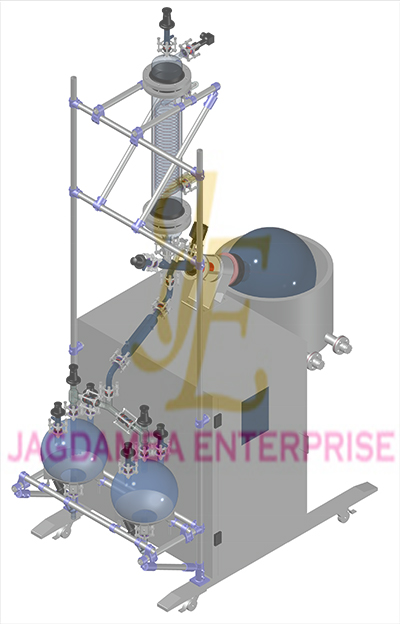

Rotary Evaporator Model Features

Principal

A Rotary evaporator can form a thin film by rotating under constant heating and specific pressures (vacuum or atmospheric). It evaporates effectively and the vapours are condensed separately and collected.Applications

- Concentration

- Solventextraction

- Crystallisation

- Petrochemistry

- Particularly handling temperature sensitivematerials

Rotary evaporator is the most effective and important apparatus for Research and development, Educational purpose and Pilot testing in Biological, biochemical, pharmaceutical, chemical, food and fragrance industry.

FEATURES OF LAB ROTARY EVAPORATORS (1L AND 2L)

- Newly designed, highly functional evaporator for improved laboratory safety andsecurity featuring solid and stableoperation.

- Ergonomically designed to make the operation easier and safer

- New vertical double coil / Helix condenser of 0.27Sq.m

- Auto jack system provides driving unit up/down by key switchoperation

- Driving unit automatically lifted up in case of powerfailure.

- Over temperature protectionsafety

- Auto poweroff

- The rotation speed displays in digital ranging from 0-180/ 5-300rpm

- 500 ml to 5000 ml interchangeable evaporating flask.

- Inbuilt control panel with LCD display, set temp, bath temp, RPM

- Great vacuum sealed performance, high evaporative capacity

- Lightweight design, easy to use and move inlaboratories

- IP20 Protection

- Large bath capacity can accommodate upto 5L flask

- CE Certification

TECHNICAL SPECIFICATIONS OF LAB SIZE ROTARY EVAPORATORS

| Specifications | JE-RE-2 | JE-RE-1 |

|---|---|---|

| Evaporation flask | 2 Lit | 1 Lit |

| Receiving flask | 1 Lit | 1 Lit |

| Speed range | 0-180 RPM | 5-300 RPM |

| Evaporation speed | 1.2 ml/min | 1.2 ml/ min |

| Heating temp range | +5 to 180 DegC | +5 to 180 DegC |

| Motor power | 40 W | 25 W |

| Water bath power | 1.5 KW | 1.3 KW |

| Condenser | Vertical triple helix condenser, cooling surface reach up to 0.27 Sq. M | Vertical triple helix with surface 0.27 sq.m |

| Rotary Shaft | Short type glass rotary shaft | Short type glass rotary shaft TS 29/38 ID 16 mm X L178 mm |

| Vacuum seal | Teflon/ teflon and viton double-deck seal | Teflon/ teflon and viton double-deck seal |

| Jack (stroke) | Electric jack slide 100mm + manual extension slide 130 mm | Electric jack slide 100mm + manual extension slide 130 mm |

| Ambient Temp. | 25 to 35 Deg.C | 25 to 35 Deg.C |

| Input power | AC220V 50Hz | AC220V 50Hz |

| Dimensions | 550 X 380 X 750 | 520 X 350 X 740 |

Our Rotary evaporators are

- Ergonomically designed to make the operation easier and safer

- 100mm motor jack slide and 130mm manual extension slide

- New vertical double coil condenser, 0.27m2, which is twice the area of ordinary condenser

- The rotation speed displays in digital, ranging from 5 ~300rpm

- Great vacuum sealed performance, high evaporative capacity

- Lightweight design made by aluminum profiles, easy to use and move in laboratories

- Teflon coated water/oil bath with safety handle to ensure the safety of the experiment, large about 4.5L can reach up to 1~2L sample flask

- Lift up to the highest point when the motor overloads

Rotary Evaporator Setup General Specifications

| Model | JE-RE-5 | JE-RE-10 | JE-RE-20 | JE-RE50 | Remarks |

|---|---|---|---|---|---|

| Evaporation Flask | 5L/50# | 10L/95# | 20L95# | 50L/125# | Table top |

| Receiving Flask | 2L/3L | 5L | 10L+5L | 10L+10L | models Options of one or two receivin g flasks |

| Motor power | 90 | 120 | 120 | 180 | Ex proof versions available |

| Bath power | 2 | 3 | 5 | 5 | – |

| Motor power | 0.096 | 0.096 | 0.096 | 0.096 | – |

| Rotation speed | 10-90 | 5-110 | 5-110 | 1-110 | 5-300 RPM |

| Evaporation speed | 2 | 3.5 | 5 | 8 | available |

| Power | 220 | 220 | 220 | 220 | – |

| Dimension (in mm) | 550 x 350 x 1100 | 1000 x 500 x 1800 | 1000 x 500 x 1800 | 1200 x 800 x 2200 | – |

For advanced models of Rotary Evaporators, please download our latest brochure

Specifications

TECHNICAL DATA OF 5L ROTARY EVAPORATOR

| Model | 5L GMP & FLP | 5L NON-GMP & FLP | 5L NON-GMP & NON-FLP |

|---|---|---|---|

| Body | SS 304 BODY | MS Powder coated | MS Powder coated |

| POWER SOURCE | Electric Panel in Flameproof Enclosure | Electric Panel in Non – Flameproof Enclosure | |

| Voltage Supply | 220V , 3Ph 50Hz | ||

| Power Consumption | 3 kW | ||

| ROTATION OF FLASK | |||

| Rotation & Controlling | Soft start & controlling with VFD | ||

| Rotation Drive | AC Synchronies Motor 0.25HP (Reputed make) | AC Synchronies Motor 0.25HP | |

| Rotation Speed | 10 to 135 | ||

| Controlling | By VFD | ||

| Distillation Rate | up to 1 – 2 L/H for water | ||

| Accuracy | 2 RPM | ||

| BATH HEATING | |||

| Temp Range | 0-180°C | ||

| Bath Heater Power | 2 kW | ||

| Bath Heating Control | Electronic with PT-100, control accuracy +/-2 ◦C | ||

| Bath Construction | Stainless steel 304 with Cover for heat protection | ||

| Bath Lift | Motorised & controlled Linear Movement by Limit switches | ||

| GLASS ASSEMBLY | |||

| Rotating Flask | 5L-1 no | ||

| Receiving Flask | 2L – 1 no (Option for twin receivers available) | ||

| Condensate Area | Vertical, 0.3 Sq.m surface area | ||

| Maximum Vacuum | 133 Pa | ||

| Safety Measures | MCB & Short Circuit Breaker , Heater Protection | ||

| Other Accessories | pipe supports, condensor holder, receiver flask holder, and rotating flask holder on bath | ||

| DISPLAY | |||

| RPM | Digital | ||

| Bath Temp | Digital with PID Controller | ||

| Vapour Temp | Digital | ||

| Time Totalizer | Digital | ||

| SENSORS | |||

| Vapour Temperature | PT – 100, 3 wire with FLP Head | PT – 100, 3 wire | |

| Bath Temperature | PT – 100, 3 wire with FLP Head | PT – 100, 3 wire | |

| Castor Wheels | All four wheels with Lock [Double Wheels] | ||

| Outer body covering (Optional) | SS-304 Body | MS Powder coated | MS Powder coated |

| Frame guard covering with transparent glass to protect the user from steam, oil spillage and accidental glass breakage. It consists of PLC and HMI with all the parameters. | |||

| Automation (Optional) | Can be hooked up with HMI & PLC for operation and storing the data. Pre defined recipe can also be integrated. | ||

TECHNICAL DATA OF 10L ROTARY EVAPORATOR

| Model | 10L GMP & FLP | 10L NON-GMP & FLP | 10L NON-GMP & NON-FLP |

|---|---|---|---|

| Body | SS 304 BODY | MS Powder coated | MS Powder coated |

| POWER SOURCE | Electric Panel in Flameproof Enclosure | Electric Panel in Non – Flameproof Enclosure | |

| Voltage Supply | 220V , 3Ph 50Hz | ||

| Power Consumption | 3 kW | ||

| ROTATION OF FLASK | |||

| Rotation & Controlling | Soft start & controlling with VFD | ||

| Rotation Drive | AC Synchronies Motor 0.25HP (Reputed make) | AC Synchronies Motor 0.25HP | |

| Rotation Speed | 10 to 135 | ||

| Controlling | By VFD | ||

| Distillation Rate | up to 3.5 – 4 L/H for water | ||

| Accuracy | 2 RPM | ||

| BATH HEATING | |||

| Temp Range | 0-180°C | ||

| Bath Heater Power | 4 kW | ||

| Bath Heating Control | Electronic with PT-100, control accuracy +/-2 ◦C | ||

| Bath Construction | Stainless steel 304 with Cover for heat protection | ||

| Bath Lift | Motorised & controlled Linear Movement by Limit switches | ||

| GLASS ASSEMBLY | |||

| Rotating Flask | 10L-1 no | ||

| Receiving Flask | 5L – 1 no (Option for twin receivers available) | ||

| Condensate Area | Vertical, 0.5 Sq.m surface area | ||

| Maximum Vacuum | 133 Pa | ||

| Safety Measures | MCB & Short Circuit Breaker , Heater Protection | ||

| Other Accessories | pipe supports, condensor holder, receiver flask holder, and rotating flask holder on bath | ||

| DISPLAY | |||

| RPM | Digital | ||

| Bath Temp | Digital with PID Controller | ||

| Vapour Temp | Digital | ||

| Time Totalizer | Digital | ||

| SENSORS | |||

| Vapour Temperature | PT – 100, 3 wire with FLP Head | PT – 100, 3 wire | |

| Bath Temperature | PT – 100, 3 wire with FLP Head | PT – 100, 3 wire | |

| Castor Wheels | All four wheels with Lock [Double Wheels] | ||

| Outer body covering (Optional) | SS-304 Body | MS Powder coated | MS Powder coated |

| Frame guard covering with transparent glass to protect the user from steam, oil spillage and accidental glass breakage. It consists of PLC and HMI with all the parameters. | |||

| Automation (Optional) | Can be hooked up with HMI & PLC for operation and storing the data. Pre defined recipe can also be integrated. | ||

TECHNICAL DATA OF 20L ROTARY EVAPORATOR

| Model | 20L GMP & FLP | 20L NON-GMP & FLP | 20L NON-GMP & NON-FLP |

|---|---|---|---|

| Body | SS 304 BODY | MS Powder coated | MS Powder coated |

| POWER SOURCE | Electric Panel in Flameproof Enclosure | Electric Panel in Non – Flameproof Enclosure | |

| Voltage Supply | 220V , 3Ph 50Hz | ||

| Power Consumption | 5 kW | ||

| ROTATION OF FLASK | |||

| Rotation & Controlling | Soft start & controlling with VFD | ||

| Rotation Drive | AC Synchronies Motor 0.25HP (Reputed make) | AC Synchronies Motor 0.25HP | |

| Rotation Speed | 10 to 135 | ||

| Controlling | By VFD | ||

| Distillation Rate | up to 3.5 – 4 L/H for water | ||

| Accuracy | 2 RPM | ||

| BATH HEATING | |||

| Temp Range | 0-180°C | ||

| Bath Heater Power | 4 kW | ||

| Bath Heating Control | Electronic with PT-100, control accuracy +/-2 ◦C | ||

| Bath Construction | Stainless steel 304 with Cover for heat protection | ||

| Bath Dimensions | Outer Ø 425 mm x 330mm deep | ||

| Bath Lift | Motorised & controlled Linear Movement by Limit switches | ||

| GLASS ASSEMBLY | |||

| Rotating Flask | 20L-1 no | ||

| Receiving Flask | 10L – 1 no (Option for twin receivers available) | ||

| Condensate Area | Vertical, 1 Sq.m surface area | ||

| Maximum Vacuum | 133 Pa | ||

| Safety Measures | MCB & Short Circuit Breaker , Heater Protection | ||

| Other Accessories | pipe supports, condensor holder, receiver flask holder, and rotating flask holder on bath | ||

| DISPLAY | |||

| RPM | Digital | ||

| Bath Temp | Digital with PID Controller | ||

| Vapour Temp | Digital | ||

| Time Totalizer | Digital | ||

| SENSORS | |||

| Vapour Temperature | PT – 100, 3 wire with FLP Head | PT – 100, 3 wire | |

| Bath Temperature | PT – 100, 3 wire with FLP Head | PT – 100, 3 wire | |

| Castor Wheels | All four wheels with Lock [Double Wheels] | ||

| Outer body covering (Optional) | SS-304 Body | MS Powder coated | MS Powder coated |

| Frame guard covering with transparent glass to protect the user from steam, oil spillage and accidental glass breakage. It consists of PLC and HMI with all the parameters. | |||

| Automation (Optional) | Can be hooked up with HMI & PLC for operation and storing the data. Pre defined recipe can also be integrated. | ||

TECHNICAL DATA OF 50L ROTARY EVAPORATOR

| Model | 50L GMP & FLP | 50L NON-GMP & FLP | 50L NON-GMP & NON-FLP |

|---|---|---|---|

| Body | SS 304 BODY | MS Powder coated | MS Powder coated |

| POWER SOURCE | Electric Panel in Flameproof Enclosure | Electric Panel in Non – Flameproof Enclosure | |

| Voltage Supply | 220V , 3Ph 50Hz | ||

| Power Consumption | 7 KW | ||

| ROTATION OF FLASK | |||

| Rotation & Controlling | Soft start & controlling with VFD | ||

| Rotation Drive | AAC Synchronies Motor 0.5HP (Reputed make) | AC Synchronies Motor 0.5HP | |

| Rotation Speed | 10 to 135 | ||

| Controlling | By VFD | ||

| Distillation Rate | up to 4 – 5.8 L/H for water | ||

| Accuracy | 2 RPM | ||

| BATH HEATING | |||

| Temp Range | 0-180°C | ||

| Bath Heater Power | 6 kw with FLP Head | 6 kw without FLP head | |

| Bath Heating Control | Electronic with PT-100, control accuracy +/-2 ◦C | ||

| Bath Construction | Stainless steel 304 with Cover for heat protection | ||

| Bath Dimensions | Outer Ø 560 mm x 400mm deep | ||

| Bath Lift | Motorised & controlled Linear Movement by Limit switches | ||

| GLASS ASSEMBLY | |||

| Rotating Flask | 50L-1 no | ||

| Receiving Flask | 20 L – 1 no (Option for twin receivers available) | ||

| Condensate Area | Vertical, 1.5 Sq.m surface area | ||

| Maximum Vacuum | 133 Pa | ||

| Safety Measures | MCB & Short Circuit Breaker , Heater Protection | ||

| Other Accessories | pipe supports, condensor holder, receiver flask holder, and rotating flask holder on bath | ||

| DISPLAY | |||

| RPM | Digital | ||

| Bath Temp | Digital with PID Controller | ||

| Vapour Temp | Digital | ||

| Time Totalizer | Digital | ||

| SENSORS | |||

| Vapour Temperature | PT – 100, 3 wire with FLP Head | PT – 100, 3 wire | |

| Bath Temperature | PT – 100, 3 wire with FLP Head | PT – 100, 3 wire | |

| Castor Wheels | All four wheels with Lock [Double Wheels] | ||

| Outer body covering (Optional) | SS-304 Body | MS Powder coated | MS Powder coated |

| Frame guard covering with transparent glass to protect the user from steam, oil spillage and accidental glass breakage. It consists of PLC and HMI with all the parameters. | |||

| Automation (Optional) | Can be hooked up with HMI & PLC for operation and storing the data. Pre defined recipe can also be integrated. | ||

TECHNICAL DATA OF 100L ROTARY EVAPORATOR

| Model | 100L GMP & FLP | 100L NON-GMP & FLP | 100L NON-GMP & NON-FLP |

|---|---|---|---|

| Body | SS 304 BODY | MS epoxy coated | MS epoxy coated |

| POWER SOURCE | Electric Panel in Flameproof Enclosure | Electric Panel in Non – Flameproof Enclosure | |

| Voltage Supply | 415V , 3Ph 50Hz | ||

| Power Consumption | 14 KW | ||

| ROTATION OF FLASK | |||

| Rotation & Controlling | Soft start & controlling with VFD | ||

| Rotation Drive | AAC Synchronies Motor 1HP (Reputed make) | AC Synchronies Motor 1HP | |

| Rotation Speed | 0 to 90 | ||

| Controlling | By VFD | ||

| Accuracy | 2 RPM | ||

| BATH HEATING | |||

| Temp Range | 0-180°C | ||

| Bath Heater Power | 6 kW X 2 | ||

| Bath Heating Control | Electronic with PT-100, control accuracy +/-2 ◦C | ||

| Bath Construction | Stainless steel 304 with Cover for heat protection | ||

| Bath Dimensions | Outer Ø 750 mm x 550mm deep | ||

| Bath Lift | Motorised & controlled Linear Movement by Limit switches | ||

| GLASS ASSEMBLY | |||

| Rotating Flask | 100L-1 no | ||

| Receiving Flask | 50 L – 1 no (Option for twin receivers available) | ||

| Condensate Area | Vertical, 1.5 / 2.5 Sq.m surface area | ||

| Maximum Vacuum | 133 Pa | ||

| Safety Measures | MCB & Short Circuit Breaker , Heater Protection | ||

| Other Accessories | pipe supports, condensor holder, receiver flask holder, and rotating flask holder on bath | ||

| DISPLAY | |||

| RPM | Digital | ||

| Bath Temp | Digital with PID Controller | ||

| Vapour Temp | Digital | ||

| Time Totalizer | Digital | ||

| SENSORS | |||

| Vapour Temperature | PT – 100, 3 wire with FLP Head | PT – 100, 3 wire | |

| Bath Temperature | PT – 100, 3 wire with FLP Head | PT – 100, 3 wire | |

| Castor Wheels | All four wheels with Lock [Double Wheels] | ||

| Outer body covering (Optional) | SS-304 Body | MS Powder coated | MS Powder coated |

| Frame guard covering with transparent glass to protect the user from steam, oil spillage and accidental glass breakage. It consists of PLC and HMI with all the parameters. | |||

| Automation (Optional) | Can be hooked up with HMI & PLC for operation and storing the data. Pre defined recipe can also be integrated. | ||

These are general specifications, it may deviate as per client’s requirement or at detailing stage.