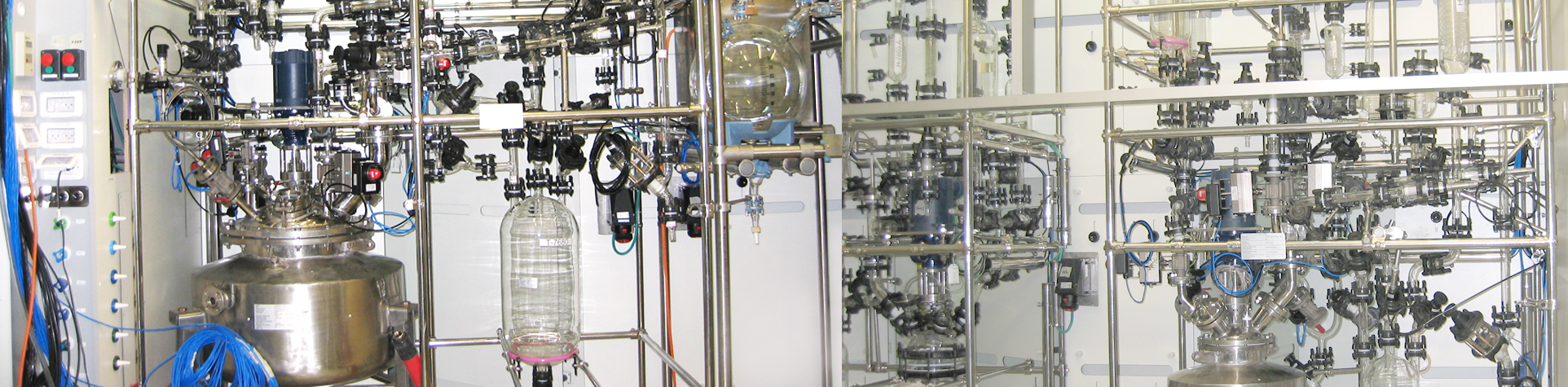

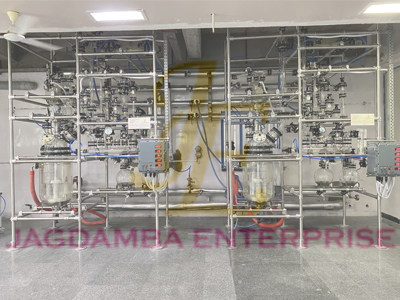

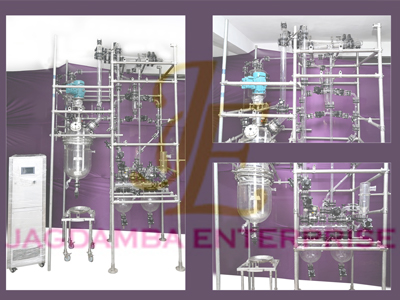

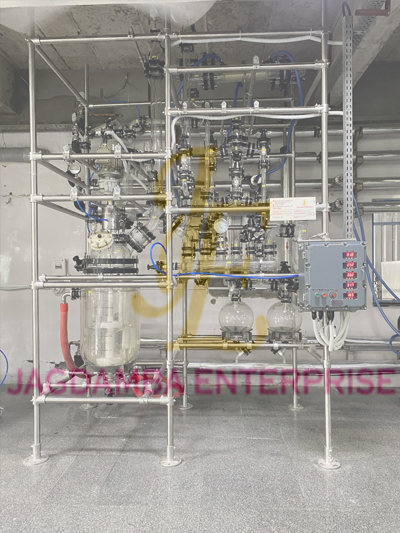

Kilo Lab systems

Products Range

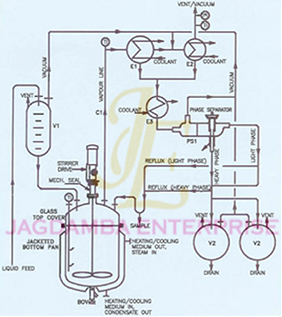

Universal Reaction/Distillation unit

Reactor Options

- Glass

- Glass lined

- Hastalloy

- SS

- Triple Wall Glass Reactor

Operating Conditions

- Temperature

- (–90°C) up to 220°C

- Pressure

- Glass Triple Wall Reactor /Glass reactor (Full vacuum up to 0.5 bar)

- SS, Hastlloy and Glass Lined reactor (Full vacuum up to 0.6 bar)

- special Design up to 20 bar

- Capacities

- 10 L up to 500 L

- Salient Features

- CGMP design

- Instrumentation & Control

- Automation with Data Acquisition

- Skid Mounted

- Documentation

Reactor Bottom Pan

- Triple wall reactors upto 100L. Both ends fused triple wall (vacuum jacketed) glass reactor

- Glass lined

- (20L, 50L, 100L, 250L)

- Pre-insulated (with SS cladding)

- jacketed

- Cylindrical Jacketed Glass (Double Wall) up to 50L

- SS, Hastalloy, Pre-insulated Jacketed

Reactor Top Cover

- Glass top cover

- Glass lined, SS, Hastalloy for pressure reactions (standard up to 6 bar, special design up to 20 bar)

Stirrer System

- Glass lined

- Anchor

- Pitch Blade turbine curved blade turbine

- PTFE lined

- Anchor

- PBT

- Paddle,etc-multistage & interchangeable impellers also available Possibl

- Glass

- Anchor

- Turbine

- Suction agitators

- Motor

- Ex-proof

- Speed control by VFD or mechanical variator

- Suitable gear box

- Seal

- Suitable MOC

- Complete SS construction (option). SS hood for motor, gearbox, housing (standard)

Bottom Outlet Valve

- Flush with zero dead volume

- Glass / PTFE

- Glass lined with temperature sensor (optional)

Reactor Bottom Pan – Raising / Lowering Device

- Manual or motorized

- Also removable after lowering

Safety Devices

- Glass / PTFE Pressure Relief Valve

- Rupture Disc

- Translucent coating of glass components

Support Structure

- Complete SS construction

- Special designs for low headrooms

- Suitable for installation in walk-in fume hoods

- Skid mounted mobile units also possible

Flanges

- Special design high strength re-enforced plastic as standard.

- SS also available as option

- SS nut bolts with compression springs as standard.

- PTFE coated as option.

Online Sampling

- Continuous on-line liquid sampling from the reactor

Single Fluid Heating Cooling Units

- Compact unit for both heating As well as cooling

- Advanced automation to precisely control temperature

- Temperature range: -90°C up to 220°C

- Fully transparent allowing clear vision of process

- Minimum time to reach desired temperature

- Compact unit

Solid Handling Systems

- Jet Mill Micronizer, Double Cone Vacuum Dryer, and Tray Dryer, Vibro-Sifters, Cream ointment & Planetary Mixer, Tripple Roll Mill / Ball Mill, Colloid Mill, Multimill

Mobile Glass Nutsche Filters

- Suitable for acidic media filtrations

- Vacuum is used to speed up filtration

- Filter plate is made of PTFE / GF

- PTFE cloth used for filter tissue

- Mounted on wheels

Mobile Gas Scrubbers

- Simple in design

- Suitable for air & Exhaust clean up tasks

- Ideal for scrubbing exhaust From small scale chemical plants

- Ideal for studies & scale-up of gas scrubber systems

Specifications

| DESCRIPTION | JE-KL-10 | JE-KL-20 | JE-KL-30 | JE-KL-50 | JE-KL-100 | JE-KL-200 | REMARKS / DETAILED DESCRIPTION |

|---|---|---|---|---|---|---|---|

| GLASS MAIN PARTS | |||||||

| Glass Cylindrical Reactor | 10L | 20L | 30L | 50L | 100L | 200L | Option available for Jacketed and Triple Wall (vacuum jacketed) available only upto 100L reactor. L/D ratio of the reactor to be maintained. |

| Top dish |

N1: DN40 (center nozzle) N2: DN25 (side nozzle) N3: DN25 (side nozzle) N4: DN50 (front nozzle) N5: DN50 (side nozzle) N6: DN15 (side nozzle) |

N1: DN50 (center nozzle) N2: DN25 (side nozzle) N3: DN40 (side nozzle) N4: DN80 (front nozzle) N5: DN80 (side nozzle) N6: DN25 (side nozzle) |

N1: DN50 (center nozzle) N2: DN25 (side nozzle) N3: DN40 (side nozzle) N4: DN100 (front nozzle) N5: DN100 (side nozzle) N6: DN25 (side nozzle) |

Option for SS-PFA lined top dish also available. Nozzle schedule can be modified based on the customer’s requirements. | |||

| SS-PTFE Lined Agitator | 1 | 1 | 1 | 1 | 1 | 1 | Option available for Anchor, PBT, CBT impeller in single as well as dual stage. Proper L/D ratio shall be maintained. |

| Drive assembly for agitator | 0.25 HP | 0.25 HP | 0.5 HP | 0.5 HP | 1 HP | 1 HP | Flameproof motor (option available for ATEX certified), gearbox, single mechanical. |

| Glass Feed Vessel | 2L | 5L | 10L | 10L | 20L | 20L | Options available in cylindrical as well as spherical vessel, also option available for twin vessels.Vessels to be graduated and calibrated. |

| Glass Receiver Vessel | 5L | 5L | 10L | 10L | 20L | 20L | Options available in cylindrical as well as spherical vessel, also option available for twin vessels as well as single vessel. Vessels to be graduated and calibrated. |

| Glass Vapour Line | DN40 | DN50 | DN80 | DN80 | DN100 | DN150 | Option available for packing inside the column – structured (eg. Ceramic) or unstructed (eg. Glass Raschig rings) packing. |

| Glass Primary Condenser | DN80-C; 0.3 sq.m | DN80-C; 0.3 sq.m | DN100-C; 0.5 sq.m | DN150-C; 1 sq.m | DN150-C; 3 sq.m | DN225-C; 6 sq.m | S – Shell & Tube Type C – Coil Type (Options available for shell & tube type as primary condenser from 50L onwards) |

| Glass Secondary Condenser | DN80-C; 0.3 sq.m | DN80-C; 0.3 sq.m | DN80-C; 0.3 sq.m | DN80-C; 0.3 sq.m | DN100-C; 0.5 sq.m | DN100-C; 0.5 sq.m | |

| Glass Phase Separator | 1L | 2L | 2L | 2L | 2L | 2L | Dean & stark type phase separator with provision of refluxing / collecting either heavy or light phase as per the demand of the process. Option for horizontal phase separator also available. |

| Glass Vacuum Manifold | DN50 | DN50 | DN50 | DN80 | DN80 | DN80 | 5 Nozzles, drain and vent |

| Glass Ice Trap | DN80 | DN80 | DN80 | DN100 | DN100 | DN100 | For trapping the escaped vapor and preventing it from fouling the vacuum pump. Ice trap to be filled with either liquid nitrogen or dry ice. |

| Glass Internal Process Pipelines | DN15 / DN25 | DN15 / DN25 | DN15 / DN25 | DN40 / DN25 | DN40 / DN25 | DN40 / DN25 | |

| Glass Main Vacuum Line | DN25 | DN25 | DN25 | DN40 | DN40 | DN40 | |

| Glass Vacuum Balance Line to Receivers / Feed Vessels | DN15 | DN15 | DN15 | DN25 | DN25 | DN25 | |

| Hardware – Plastic flanges, Inserts , SS Nuts, bolts, washers and springs | SET | SET | SET | SET | SET | SET | Plastic flanges used as per DIN standard. Option available for SS-304 / SS-316 flanges too. |

| Structure – Main Frame – SS304 | 1″ SCH40 pipe | 1″ SCH40 pipe | 1″ SCH40 pipe | 1.25″ SCH40 pipe | 1.25″ SCH40 pipe | 1.25″ SCH40 pipe | Option available for reactor vessel lifting and lowering with limit switches. |

| SAFETY FEATURES | |||||||

| Rupture Disc | DN40 / DN50 | DN40 / DN50 | DN40 / DN50 | DN40 / DN50 | DN40 / DN50 | DN40 / DN50 | Suitable to withstand vacuum and burst pressure rating of 0.6 bar @ 100 DegC. |

| AUTOMATION AND INSTRUMENTATION | |||||||

| Temperature Sensors | 4 | 4 | 4 | 4 | 4 | 4 | Reactor temp, Vapour temp, Vent temp and Product temp. Sensor of reputed make (FLP enclosure) Duplex 3 wire Class A PT100 sensors to be used. |

| Pressure Transmitter / Dial Gauge | 1 | 1 | 1 | 1 | 1 | 1 | Please choose between pressure transmitter and dial gauge as per your requirement. |

| Agitator RPM controller (VFD) | 1 | 1 | 1 | 1 | 1 | 1 | Reputed make VFD to be used. |

| Operation & Indication Panel | 1 | 1 | 1 | 1 | 1 | 1 | Option available for: 1) Ex d enclosure (Ex II 2GD Ex DB) 2) PLC with ATEX / NON-ATEX approved HMI |

| HMI with PLC panel (Optional) | Touchscreen HMI can be provided inside flameproof enclosure along with PLC panel | Option available for: 1) Ex d enclosure (Ex II 2GD Ex DB) 2) PLC to be placed in safe area. |

|||||

| SCADA Automation Solution (Optional) | PC workstation for controlling, storing and reviewing of process parameters of the assembly | CFR21 PART 11 compliant SCADA automation solutions, pre-defined recipe formulation as per process requirements also available. | |||||

| ADDITIONAL ACCESSORIES / INFORMATION | |||||||

| Reactor lifting and lowering system | Stainless steel lifting and lowering system for reactor vertical movement (up & down) | Used for cleaning and ease of agitator interchangeability. | |||||

| Heating & Cooling system | Different models of several temperature ranges and power (kW) are available | Do visit our product page (temperature control unit) for selection of the right model. | |||||

| Documentation (Optional) | SET | SET | SET | SET | SET | SET | Complete set of documentations and certifications to be provided along with the system. |

| Approximate Foot Print | L: 1900 mm W: 1200 mm H: 3100 mm |

L: 2000 mm W: 1000 mm H: 3300 mm |

L: 2000 mm W: 1200 mm H: 3300 mm |

L: 2150 mm W: 1300 mm H: 3300 mm |

L: 2400 mm W: 1500 mm H: 3800 mm |

L: 2650 mm W: 1500 mm H: 4200 mm |

Based on the client’s requirements, we can modify the system and try to accommodate in the available area. These footprint area is approximate, do confirm with us once. |

These are general specifications, it may deviate as per client’s requirement or at detailing stage.