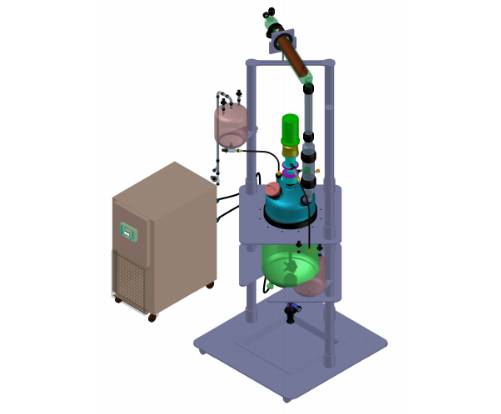

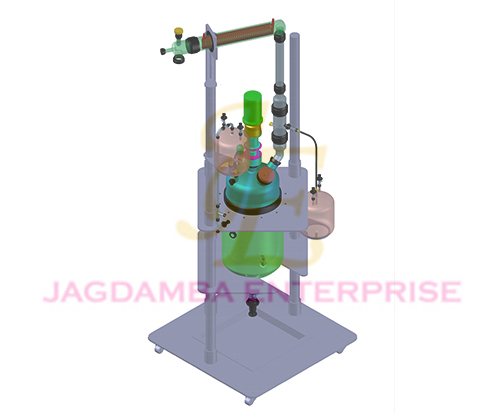

Pilot Reactor System

- Vessel Capacity: 5L, 10L, 15L, 20L, 50L, 100L

- Vessel Type: Jacketed and Triple Wall

- Operating Pressure: Full Vacuum to 0.5 bar G

- Operating Temperature: -50 °C to 200 °C

Parts

- Cylindrical Vessel

- Vessel Cover

- Quick Release Coupling

- O-Ring

- Flush Bottom Valve

- PTFE Stirrer

- Man Hole

- Thermometer Pocket

- Condenser with reflux

- Product Cooler

- Addition Vessel

- Receiver Vessel

- Vent

- Support Structure

Specifications

| DESCRIPTION | JE-PS-10 | JE-KL-20 | JE-KL-30 | JE-KL-50 | JE-KL-100 | JE-KL-200 | REMARKS / DETAILED DESCRIPTION |

|---|---|---|---|---|---|---|---|

| GLASS MAIN PARTS | |||||||

| Glass Cylindrical Reactor | 10L | 20L | 30L | 50L | 100L | 200L | Option available for Jacketed and Triple Wall (vacuum jacketed) available upto 100L reactor. L/D ratio of the reactor to be maintained. |

| Top dish |

N1: DN40 (center nozzle) N2: DN25 (side nozzle) N3: DN25 (side nozzle) N4: DN50 (front nozzle) N5: DN50 (side nozzle) N6: DN15 (side nozzle) |

N1: DN50 (center nozzle) N2: DN25 (side nozzle) N3: DN40 (side nozzle) N4: DN80 (front nozzle) N5: DN80 (side nozzle) N6: DN25 (side nozzle) |

N1: DN50 (center nozzle) N2: DN25 (side nozzle) N3: DN40 (side nozzle) N4: DN100 (front nozzle) N5: DN100 (side nozzle) N6: DN25 (side nozzle) |

Option for SS-PFA lined top dish also available. Nozzle schedule can be modified based on the customer’s requirements. | |||

| SS-PTFE Lined Agitator | 1 | 1 | 1 | 1 | 1 | 1 | Option available for Anchor, PBT, CBT impeller in single as well as dual stage. Proper L/D ratio shall be maintained. |

| Drive assembly for agitator | 0.25 HP | 0.25 HP | 0.5 HP | 0.5 HP | 1 HP | 1 HP | Flameproof motor (option available for ATEX certified), gearbox, single mechanical seal (reputed make) and SSPTFE lined agitator. |

| Glass Feed Vessel | 2L | 5L | 10L | 10L | 20L | 20L | Options available in cylindrical as well as spherical vessel, Vessels to be graduated and calibrated |

| Glass Receiver Vessel | 5L | 5L | 10L | 10L | 20L | 20L | Options available in cylindrical as well as spherical vessel. Vessels to be graduated and calibrated |

| Reflux Divider | DN50 | DN50 | DN80 | DN80 | DN100 | DN150 | Option available in manual as well as pneumatic operated automatic relfux divider. |

| Condenser | DN80-C; 0.3 sq.m | DN80-C; 0.3 sq.m | DN100-C; 0.5 sq.m | DN150-C; 1 sq.m | DN150-C; 1.5 sq.m | DN225-C; 2.5 sq.m | C- Coil type condenser |

| Glass Internal Process Pipelines | DN15 / DN25 | DN15 / DN25 | DN25 | DN25 | DN25 | DN25 | |

| Hardware – Plastic flanges, Inserts , SS Nuts, bolts, washers and springs | SET | SET | SET | SET | SET | SET | Plastic flanges used as per DIN standard. Option available for SS-304 / SS-316 flanges too. |

| Structure – Main Frame | Suitable size structure to be used. | Options available in SS and MS epoxy coated. | |||||

| SAFETY FEATURES | |||||||

| Rupture Disc | DN40 / DN50 | DN40 / DN50 | DN40 / DN50 | DN40 / DN50 | DN40 / DN50 | DN40 / DN50 | Suitable to withstand vacuum and burst pressure rating of 0.6 bar @ 100 DegC. |

| AUTOMATION AND INSTRUMENTATION | |||||||

| Temperature Sensors | 3 | 3 | 3 | 3 | 3 | 3 | Reactor temp, Reflux temp, Vent temp. Sensor of reputed make (FLP enclosure) Duplex 3 wire Class A PT100 sensors to be used. |

| Agitator RPM controller (VFD) | 1 | 1 | 1 | 1 | 1 | 1 | Reputed make VFD to be used |

| Operation & Indication Panel | 1 | 1 | 1 | 1 | 1 | 1 | Option available for : 1) Ex d enclosure (Ex II 2GD Ex DB) 2) PLC with ATEX / NON-ATEX approved HMI. |

| HMI with PLC panel (Optional) | Touchscreen HMI can be provided inside flameproof enclosure along with PLC panel | Option available for : 1) Ex d enclosure (Ex II 2GD Ex DB) 2) PLC to be placed in safe area. |

|||||

| SCADA Automation Solution (Optional) | PC workstation for controlling, storing and reviewing of process parameters of the assembly. | CFR21 PART 11 compliant SCADA automation solutions, pre-defined recipe formulation as per process requirements also available. | |||||

| ADDITIONAL ACCESSORIES / INFORMATION | |||||||

| Reactor lifting and lowering system | Stainless steel lifting and lowering system for reactor vertical movement (up & down) – manual or automatic | Used for cleaning and ease of agitator interchangeability | |||||

| Heating & Cooling System | Different models of several temperature ranges and power (kW) are available. | Do visit our product page (temperature control unit) for selection of the right model. | |||||

| Documentation (Optional) | SET | SET | SET | SET | SET | SET | Set of documentations and certifications to be provided along with the system. |

These are general specifications, it may deviate as per client’s requirement or at detailing stage.