Glass Shell & Tube Heat Exchangers

- Main Condensers

- Guard Condensers

- Product Coolers

- Thermo-siphon Reboilers

- Waste Heat Economizers

- Also with SiC tubes

- Special design high pressure heat exchangers

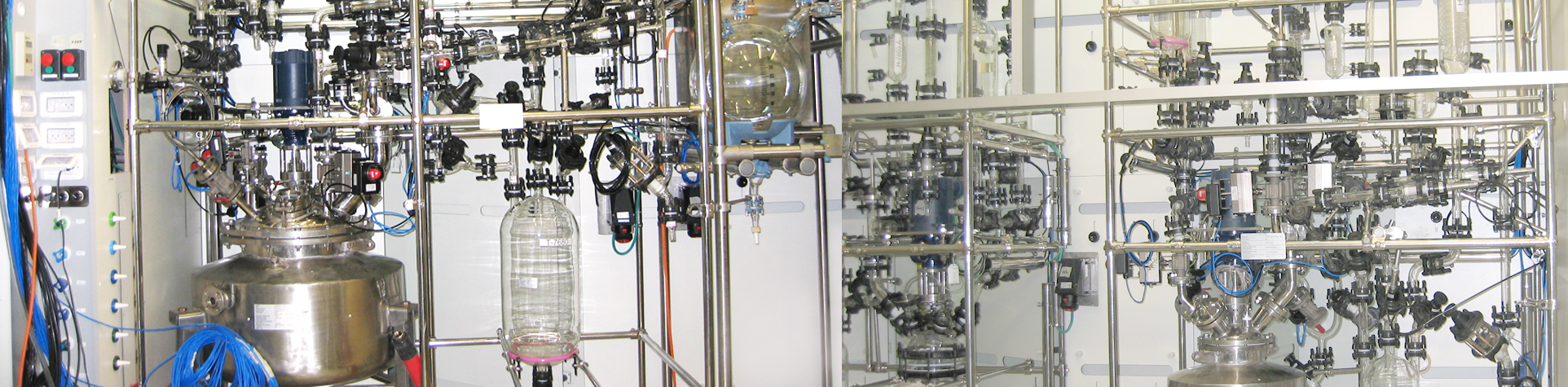

Shell & Tube Heat Exchangers are particularly suitable for applications where large heat transfer areas are required in relatively confined spaces.

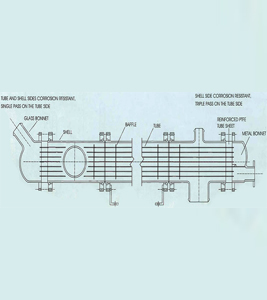

Shell & Tube heat exchangers are available in single pass as well as multi-pass on tube side material of construction of tube :

- Borosilicate Glass

- Titanium

- Graphite

- Silicon Carbide

- Tantalum

- Stainless Steel

Material of construction of shell may be

- Borosilicate Glass

- FRP

- MS-PTFE lined

- Mild Steel

- Stainless Steel

- MS Glass Lined

Tube sheets are invariably of Glass Reinforced PTFE Applications

- Condenser

- Reboiler

- Gas / Liquid Cooler

- Waste Heat Economizer

- Typical Heat Transfer Coefficients in kcal/m2.°C.hr

- Cooling Water

- Condensing Steam 350-550

- Cooling Water-Water: 250-350

- Cooling Water-Air 30-60

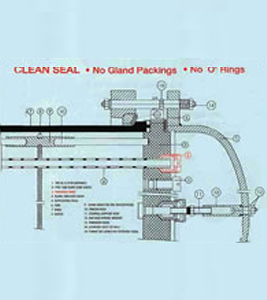

Shell & Tube Heat Exchangers supplied by ATR-GLASS have unique features. Instead of ordinary seals with gland packings and ‘O’rings, there is an integral ferrule in the sealing bush, making a clean perfect seal. Also the tie rods are glass as standard.

The Heat Exchanger is well standardized, it is easy to procure spares.

Salient Features

- Universal Corrosion Resistance

- Outstanding heat transfer

- Space-saving arrangement by installing in Horizontal or Vertical position

- Simple replacement of inner tubes for repair and cleaning

- Low Maintenance cost

- Standard Shell & Tube Heat Exchangers are available in range of 2.5 m2 to 25.0 m2