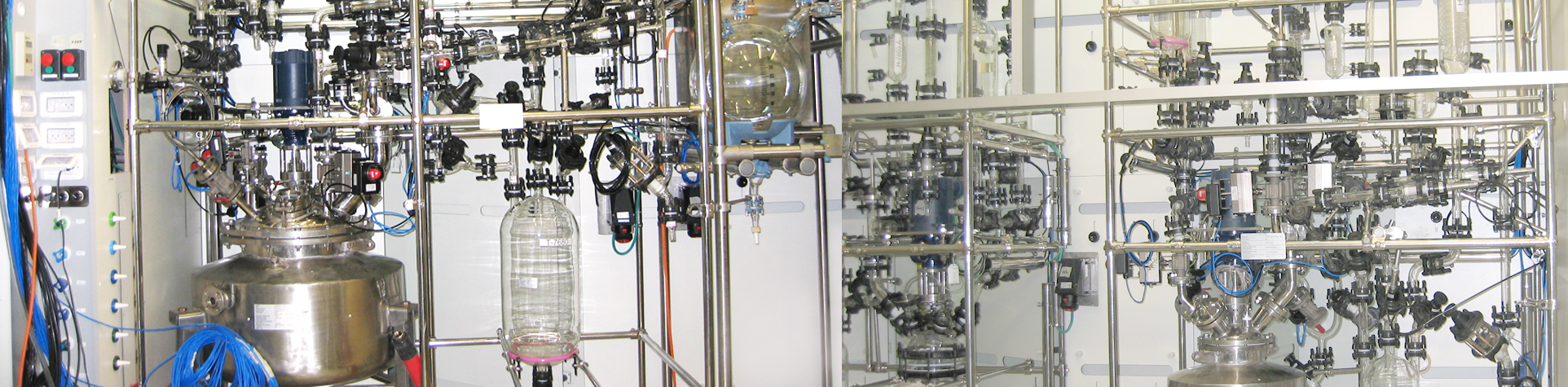

Engineered Systems (Glass Assemblies)

Over Head Assembly on Glasslined Vessel

- Borosilicate Glass overhead assembly can be easily fitted to Glass-Lined, SS or other metal / coated reaction vessels.

- The reaction system is specifically useful for production of highly refined and highly pure products such as fine chemicals, pesticides, vitamins and pharmaceuticals.

- The system is highly corrosion resistant.Because of modular construction, changes can be made in the overhead structure depending upon process requirements.

- Borosilicate Glass permits visual observation.

Distillation

The Distillation Equipment consists of:

- Column with packing and internals

- Primary condensor

- Secondary condensor

- Distillate cooler

- Phase separator (optional)

- Receivers

- Metric grid construction offers option of reorganizing.

- Highly corrosion resistant.

- Visual observation possible.

Evaporation

- Evaporation of large quantities of liquids is possible without damaging active ingredient.

- Fabricated from borosilicate glass and so highly corrosion resistant and offers visual observation.

- Proper design shall give energy efficient system.

Type of Systems:

- Simple evaporator with reboiler

- Falling-Film evaporator

- Wiped-Film evaporator

Extraction

- For difficult separation problems such as liquids having virtually same boiling points, forming azeotropic mixtures or perhaps temperature sensitive, extraction offers economical solution.

- Mixer-settler

- Spray towers

- Unpulsed sieve plate columns

- Pulsed sieve plate and packed columns

- Stirred columns

The Following Type of Equipments is Available:

Absorption

- To separate gas mixtures as required by the process

- To purify a component of a gas mixture

- To recover valuable components from waste gases

- To remove harmful gases from waste gases

- Borosilicate Glass offers best material of construction as it is corrosion resistant.

- Visual monitoring possible.

- Because of modular construction, changes in system possible.

The objectives of absorption are:

Crystallization

Depending on the specifications for the end products such as:

- Particle size

- Particle size distribution

- Product purity

- A wide range of crystallizer types is available for coping with manifold crystallization problems. The criteria for selecting the crystallization process are the physical properties of the solutionsand products and also economic considerations.

Glass Venturi Scrubber

- Easy Operation q No moving parts

- Intimate mixing

- Compact Installed on Tank

- Creates vacuum

Specifications

| DESCRIPTION | JE-OA-63 | JE-OA-160 | JE-OA-250 | JE-OA-500 | JE-OA-1000 | JE-OA-2500 | JE-OA-5000 | REMARKS / DETAILED DESCRIPTION |

|---|---|---|---|---|---|---|---|---|

| Glass Feed Vessel | 10L | 20L | 50L | 50L | 100L | 100L X 2 Nos. | 100L X 2 Nos. | Option available for twin feed vessels, cylindrical / spherical vessels as per client’s requirement. Vessels will be graduated and calibrated. |

| Glass Receiver Vessel | 10L | 20L | 50L | 50L | 100L | 100L X 2 Nos. | 100L X 2 Nos. | Option available for twin feed vessels, cylindrical / spherical vessels as per client’s requirement. Vessels will be graduated and calibrated. |

| Glass Vapour Line | DN100 | DN100 | DN150 | DN250 | DN250 | DN300 | DN300 | Vapor column can be with / without packing as per client’s requirement. |

| Glass Primary Condenser | DN150-C; 1 sq.m | DN150-C; 1.5 sq.m | DN225-C; 2.5 sq.m | DN225-S; 6 sq.m | DN225-S; 10 sq.m | DN300-S; 16 sq.m | DN300-S; 25 sq.m | S – Shell & Tube Type C – Coil Type |

| Glass Secondary Condenser | DN80-C; 0.3 sq.m | DN100-C; 0.5 sq.m | DN100-C; 0.5 sq.m | DN150-C; 1 sq.m | DN150-C; 1.5 sq.m | DN150-S; 3 sq.m | DN150-S; 4 sq.m | S – Shell & Tube Type C – Coil Type |

| Glass Internal Process Pipelines | DN25 | DN25 | DN40 / DN25 | DN40 / DN25 | DN40 / DN25 | DN40 / DN25 | DN40 / DN25 | Condensate outlet & reflux line |

| Hardware – Plastic flanges, Inserts , SS Nuts, bolts, washers and springs | SET | SET | SET | SET | SET | SET | SET | Plastic flanges used as per DIN standard. Option available for SS-304 / SS-316 flanges too. |

| Structure – Main Frame | Suitable size structure to be selected. MOC options of stainless steel and mild steel with epoxy coating available. | |||||||

| Rupture Disc | DN40 / DN50 | DN40 / DN50 | DN40 / DN50 | DN40 / DN50 | DN40 / DN50 | DN40 / DN50 | DN40 / DN50 | Suitable to withstand vacuum and burst pressure rating of 0.6 bar @ 100 DegC. |

| Temperature Sensors (Optional) | 3 temp points considered with indication on the panel – vapor, product and vent. | Sensor of reputed make (FLP enclosure) Duplex 3 wire Class A PT100 sensors to be used. | ||||||

| Documentation (Optional) | SET | SET | SET | SET | SET | SET | SET | Complete set of documentation and certifications will be provided. |

These are general specifications, it may deviate as per client’s requirement or at detailing stage.